A Biased View of Glazing Infill Panels

Where the air vent openings are 12 inches (305 mm) or less in the very least measurement and also are limited in procedure to turn down objects as needed for protect in Area R4403.7.3. 2. Slats or grille job constructed to abide with Common OSHA-1910, established forth in Area R4403.7.3 of this code, or other building and construction authorized by the structure authorities, may be given in lieu of other safeguards.

Where the close to side of such home windows is much less than 4 inches (102 mm) above the floor and also falling things could present a risk, toeboards will be provided as required by 29 CFR 1910. 4. Alternate authorized designs. R4410.2.5.2 Where the decline from such windows is less than 4 feet (1219 mm) or where such windows adjoin a door, the glazing will follow Areas R4410.2.4.2 as well as R4410.2.4.3.

R4410.2.6.1 Swinging or gliding doors of glass without a continuous framework will be of only fully tempered glass not much less than 3/8 inch (9.5 mm) in thickness. R4410.2.6.2 Safeguards. The glazing in sliding and turning doors as well as in shower to bathtub rooms, including any type of glazing within 60 inches (1.5 m) of the completed floor surface area in wall surfaces bordering any type of tub or shower enclosure, shall be security glazing as set forth in Section R4410.2.3.1.3 for Classification II glazing items.

R4410.2.6.4 The glazing in dealt with panels adjacent to courses of egress shall adhere to Area R4410.2.4.3. R4410.2.6.5 Glass shall not be solid repainted or otherwise hid where such painted glass may be misinterpreted for other building and construction materials. R4410.2.6.6 Glass mirrors of more than 9 square feet (0.84 m2) in area that are utilized as surface coating product on wall surfaces in public spaces will be straight secured to assistances and also will not be hung.

Not known Factual Statements About Infill Panels For Windows

R4410.2.7.1 Safety glazing, where called for, shall be as set forth in this area. R4410.2.7.2 Safety glazing will follow the basic state in Area R4410.2.1.4 for transparent as well as unknown safety-glazing materials, as well as plastic glazing shall additionally abide by the specs of Area R4410.2.7.3. R4410.2.7.3 Plastics, with or without reinforcing or acrylic modifiers shall adhere to Section R4412.1, and factor to consider of dimension decrease triggered by deflection and/or dimensional instability of the materials shall be given in the determination of the deepness of the glazing rabbet and involvement of the plastic in the rabbet.

R4410.2.7.4 Glass louvered doors require not be safety glazed. R4410.2.8 Sloped glazing. R4410.2.8.1 Sloped glazing includes any type of installation of glass or other transparent, translucent or nontransparent glazing product installed at a slope of 15 degrees (0.26 rad) or extra from the vertical airplane. Glazing products in skylights, roofings and also sloped wall surfaces are included with this definition.

Sloped polishing shall be any one of the complying with products based on the restrictions specified in Area R4410.2.8.3. R4410.2.8.2.1 For monolithic glazing systems, the glazing product of the single light or layer shall be laminated flooring with a minimal 30 mil polyvinyl butyryl (or comparable) interlayer, cable glass, approved plastic material meeting the demands of this Area, heat strengthened glass or totally solidified glass.

R4410.2.8.2.3 See Area R4412.1 for added demands for plastic skylights. R4410.2.8.3 Limitations. Warm enhanced as well as totally solidified glass when used in monolithic glazing systems shall have screens installed below the glazing material to shield building passengers from falling glass needs to breakage happen. The displays shall be capable of supporting the weight of the glass as well as will be considerably supported below and also installed within 4 inches (102 mm) of the glass.

The Greatest Guide To Glass Infill Panels For Stairs

In a destructive atmosphere structurally equivalent corrosion-resistant screening materials will be utilized. Heat-strengthened glass, fully toughened up glass and cable glass, when made use of in multiple glazing systems as the lower layer over the strolling surface, will be equipped with screening meeting the needs for monolithic glazing systems. Exemptions: 1. In monolithic and numerous layer sloped polishing systems, any kind of glazing product, including stiff glass, might be mounted without called for screens if the walking surface listed below the glazing material is permanently secured from the risk of falling glass or if the area listed below the glazing product is not a walking surface area.

In monolithic and numerous layer sloped glazing systems, any glazing material, consisting of annealed glass, might be mounted in the sloped glazing systems of greenhouses (structures made use of mostly for expanding plants) without displays gave the height of the penthouse at the ridge does not surpass 20 feet (6.1 m) above grade. in fill panels.

In various other instances, fireproof frameworks shall be made use of. R4410.2.8.4 Sloped glazed framing. In apart from Types IV, IIB as well as IIIB construction, all sloped polishing skylight frameworks will be constructed of noncombustible materials. In foundries or buildings where acid fumes unhealthy to metal are incidental to using the building, accepted stress dealt with woods or other accepted fireproof material shall be allowed for sash and frameworks (glass infill panels for stairs).

All skylights evaluated an angle of much less than 45 levels (0.79 rad) from the straight shall be mounted at the very least 4 inches (102 mm) over the planer of the roofing system on a visual construction as required for the structure. glazing infill panels. Sloped glazing might be set up in the plane of the roofing where the roofing system pitch is higher than 45 degrees (0.79 rad) from the straight.

Getting The Glass Infill Panels To Work

R4410.3.2 Dimension. Glass-veneer devices will be not less than 11/32 inch (8.7 mm) in thickness. No device will be larger in location than 10 square feet (0.93 m2) where 15 feet (4.6 m) or less over the grade straight below, neither larger than 6 square feet (0.56 m2) where more than 15 feet (4.6 m) above the grade directly below.

Every glass-veneer unit will be affixed to the support with approved mastic concrete and also corrosion-resistant connections as well as shall be supported on shelf angles. R4410.3.3.1 Where even more than 6 feet (1829 mm) over grade, veneer will be sustained by rack angles, and also connections will be used in both horizontal as well as vertical joints.

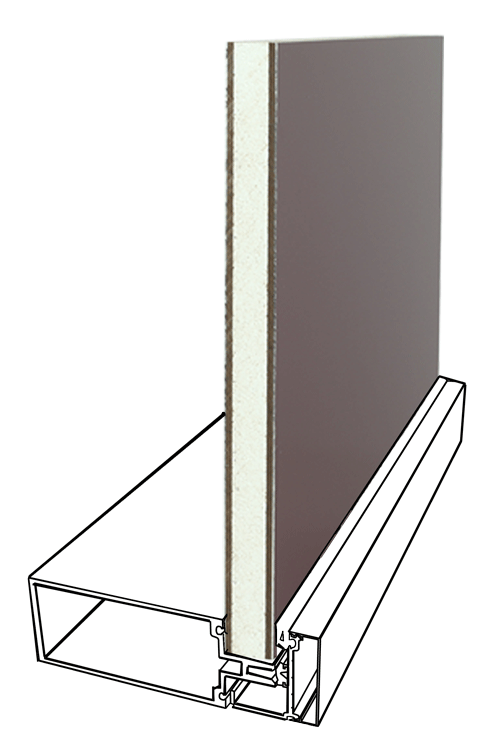

spandrel panel curtain wall detail glass glazing putty infill panel design